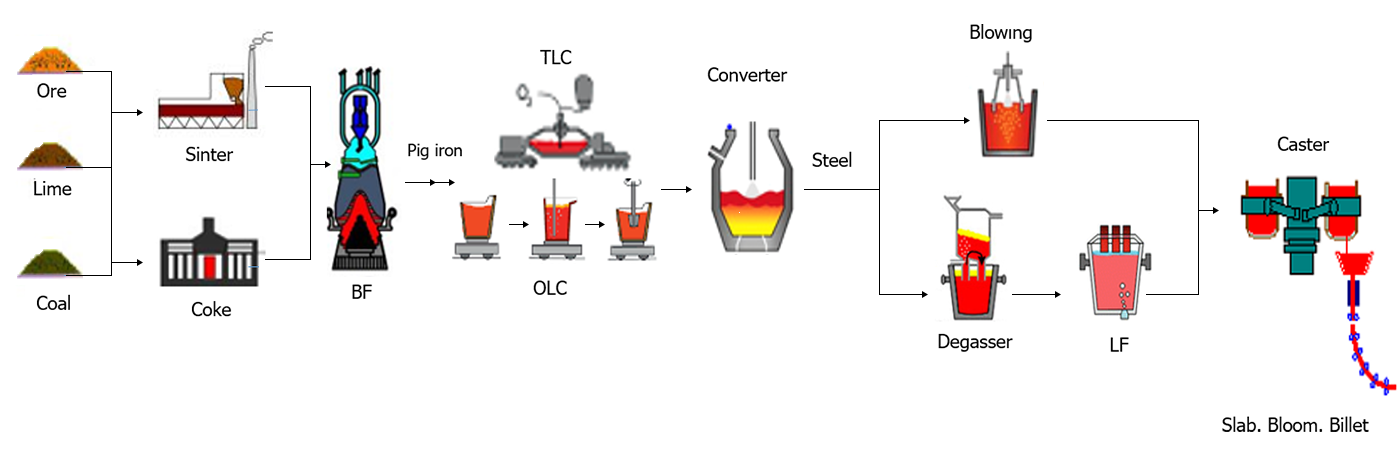

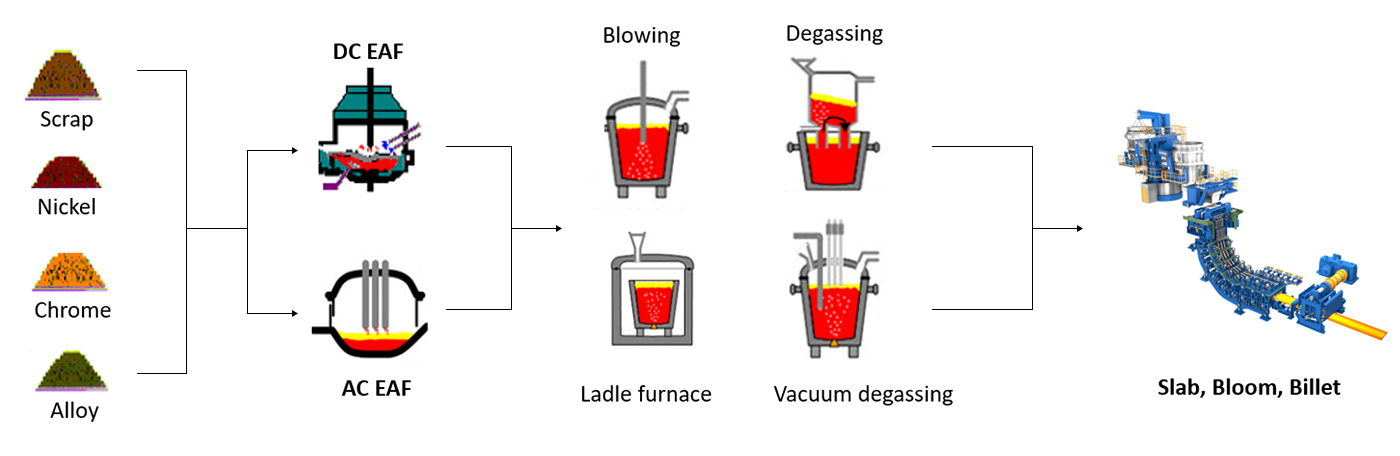

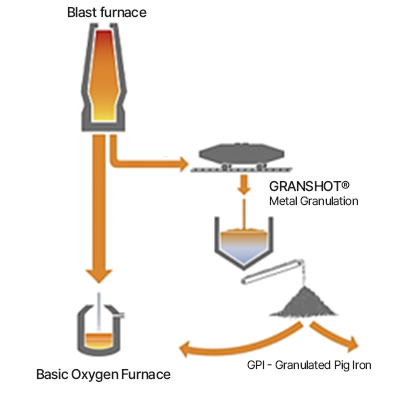

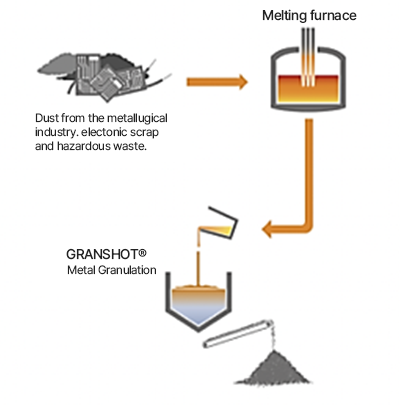

Iron Making

Steel Making & Refining

Continuous Casting

New & Renewable Energy

advanced technology solution service provider

ats provides the advanced technical solution to customers with engineering, consulting and collaboration

management through proven technology

and global outsourcing net work for industrial plants.

ats focus on supporting a customized service based on economical engineering and project management together

with partners.

You can rely on ats to lead or to assist with the relevant technical, regulatory and commercial

steps to realize your business

.png)

.png)

.png)

.png)